Machining

New Hampshire Hydraulics maintains a full scale in-house machine shop which enables us to quickly produce replacement parts for the hydraulic cylinders we service. The following is an overview of the common parts we produce and our capabilities.

CYLINDER PARTS:

Cylinder rods: When cylinder rods are damaged beyond economical repair due to scoring, bending, breaking or other

damage, we are able to economically replicate the rod to save time & money!

- We stock 45+ sizes of chromed rod stock in both standard & metric, much of which is induction-hardened.

- We have additional materials available for special applications such as chrome-over-stainless steel for harsh environments.

- Complex configurations are no problem for our highly skilled and experienced machinists.

- In most cases we will re-use the existing rod eye to save you additional money. All rod eyes are inspected for roundness, cracks or other damage. Worn bushings & swivel bearings are replaced as required from our vast stock of components. If the rod eye is not re-usable, we fabricate new.

Cylinder barrels (cases):

Cylinder barrels (cases): Cylinder barrels can be damaged beyond repair due to internal scoring, dents, cracking or corrosion.

- We stock multiple sizes of hydraulic grade honed ID tubing in both standard & metric to quickly fabricate new barrels.

Glands:

Glands: We stock the raw materials needed to fabricate newly machined glands. In many cases we can repair the gland by

building it up with weld and re-machining it to “like new” or better condition.

Piston heads: We stock the raw materials needed to fabricate newly machined piston heads. In many cases we can repair the

piston head by building it up with weld and re-machining it to “like new” or better condition.

MACHINE SHOP CAPABILITIES:

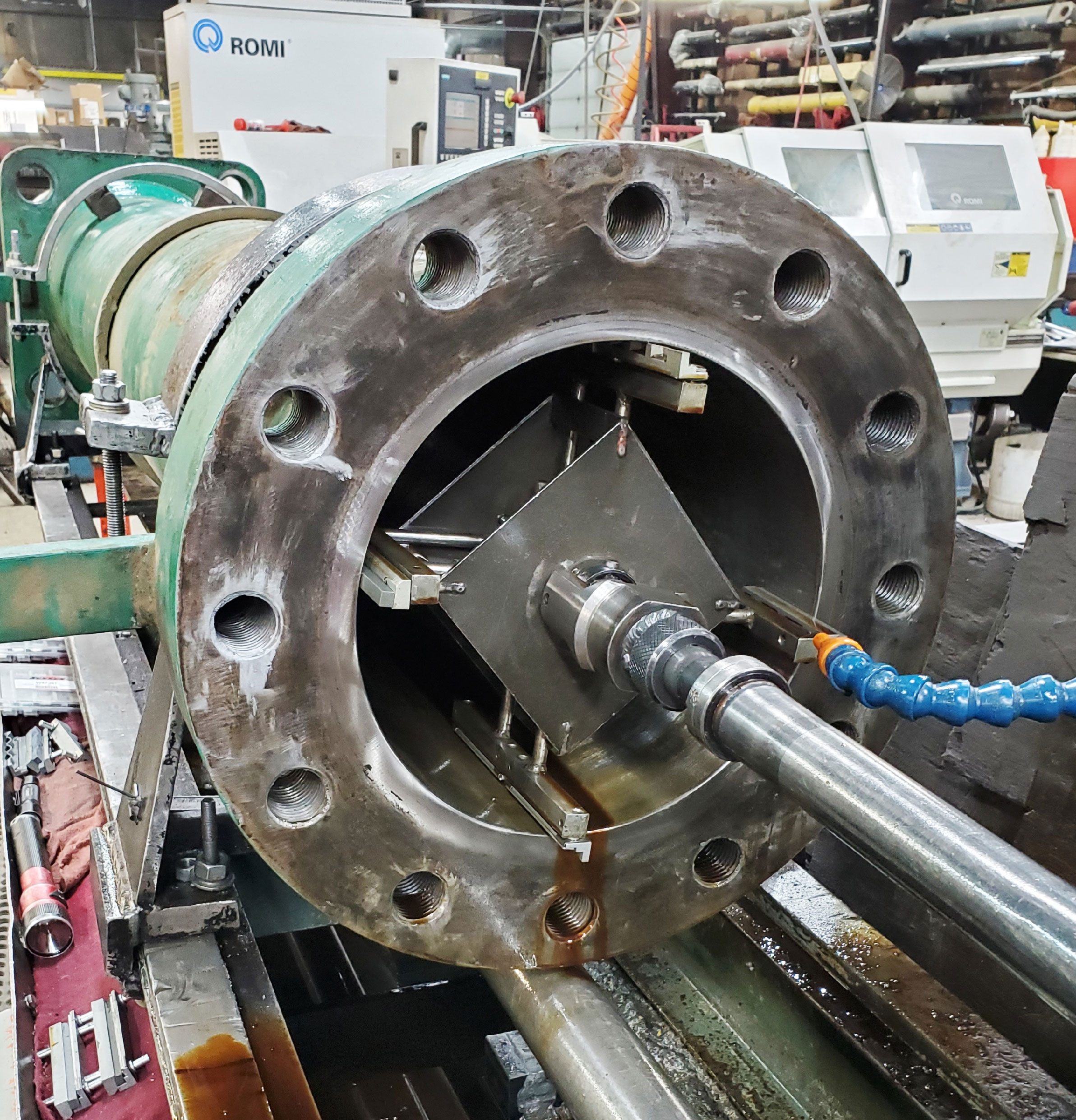

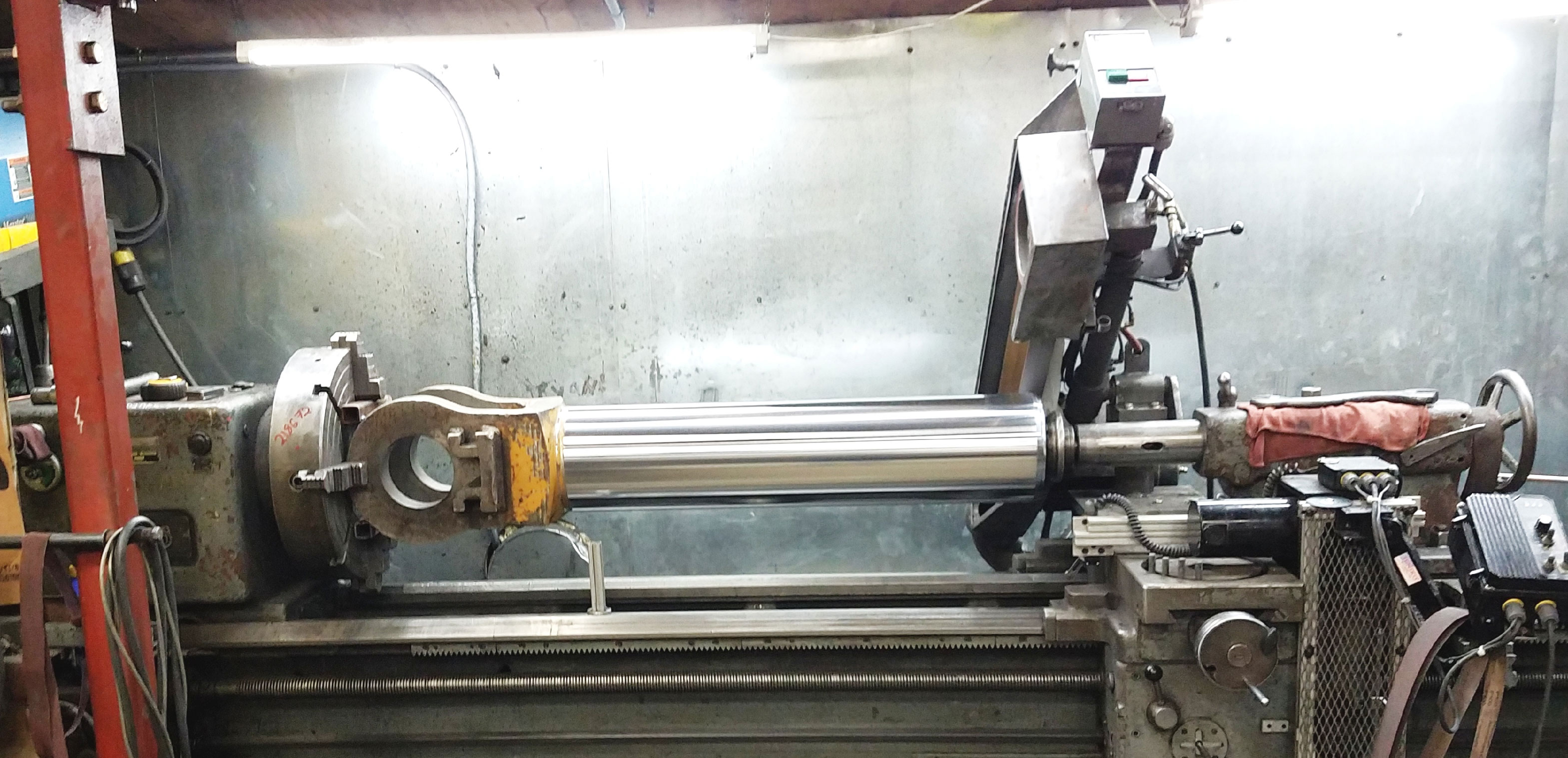

Lathes: 10 lathes total including

- Large Bore, up to 30” x 27’ capacity

- Long Length 10” hole Thru-Lathe, up to 40’ long capacity or even longer

- CNC, for quantity runs of identical parts

Various Milling Machines: We are able to mill, shape and drill as needed for repair and fabrication of parts.

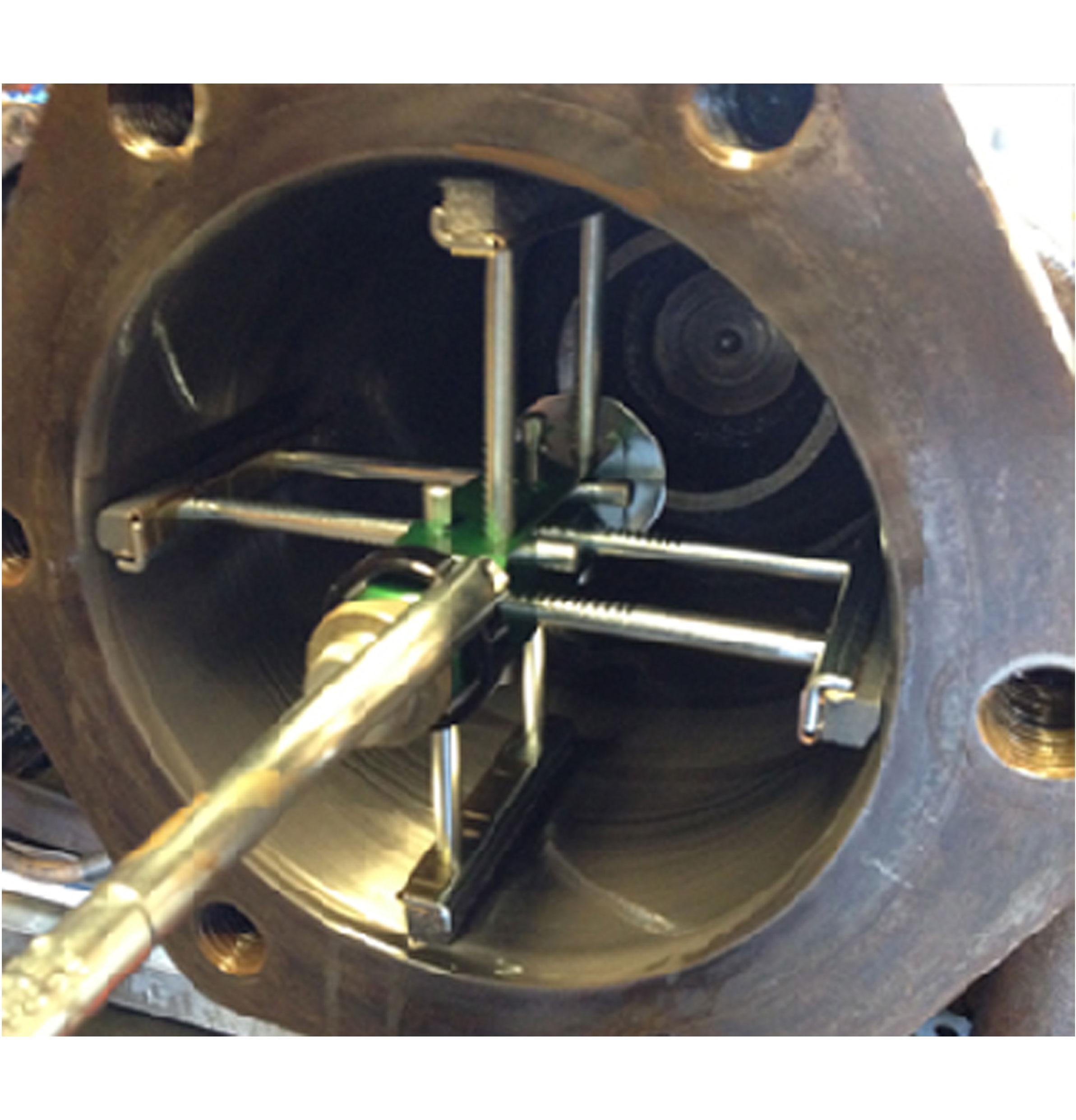

Honing Machines: A properly honed tube is the basis for a superb seal, smooth operation and extended seal life for any hydraulic cylinder. Every time a cylinder is resealed, light honing should be performed as part of a thorough repair. A hone job will renew the bore finish and provide a true bore that is necessary to achieve maximum life, peak performance and reduced downtime.

In some instances, cylinder damage is too severe and a light hone will not be sufficient. In such cases, the hydraulic repair experts at New Hampshire Hydraulics can offer several options for a sound repair such as “heavy hone” & “refit”.

Spin Polishing: For chromed rods & cylinder stages New Hampshire Hydraulics has a Spin Polishing machine to remove minor damage to the sealing surface. Rods with minor damage to the chrome can be weld repaired, ground and spin polished to save the rod from needing to be replaced, saving money on the repair.